Hazardous Areas

Keeping your electrical hazard areas working properly

Ensuring a safe workplace is a crucial responsibility for P.C.B.U/Owners.

Are you aware of the explosive gases and combustable dusts present in your plant or processes?

Here at ICE Electrical, We have the expertise to identify and help you to make sure that you run smoothly without having a sudden stop to your work or putting your staff, equipment and products at danger.

What are combustable dust particles?

Combustable dust particles are an unavoidable part of the manufacturing process.

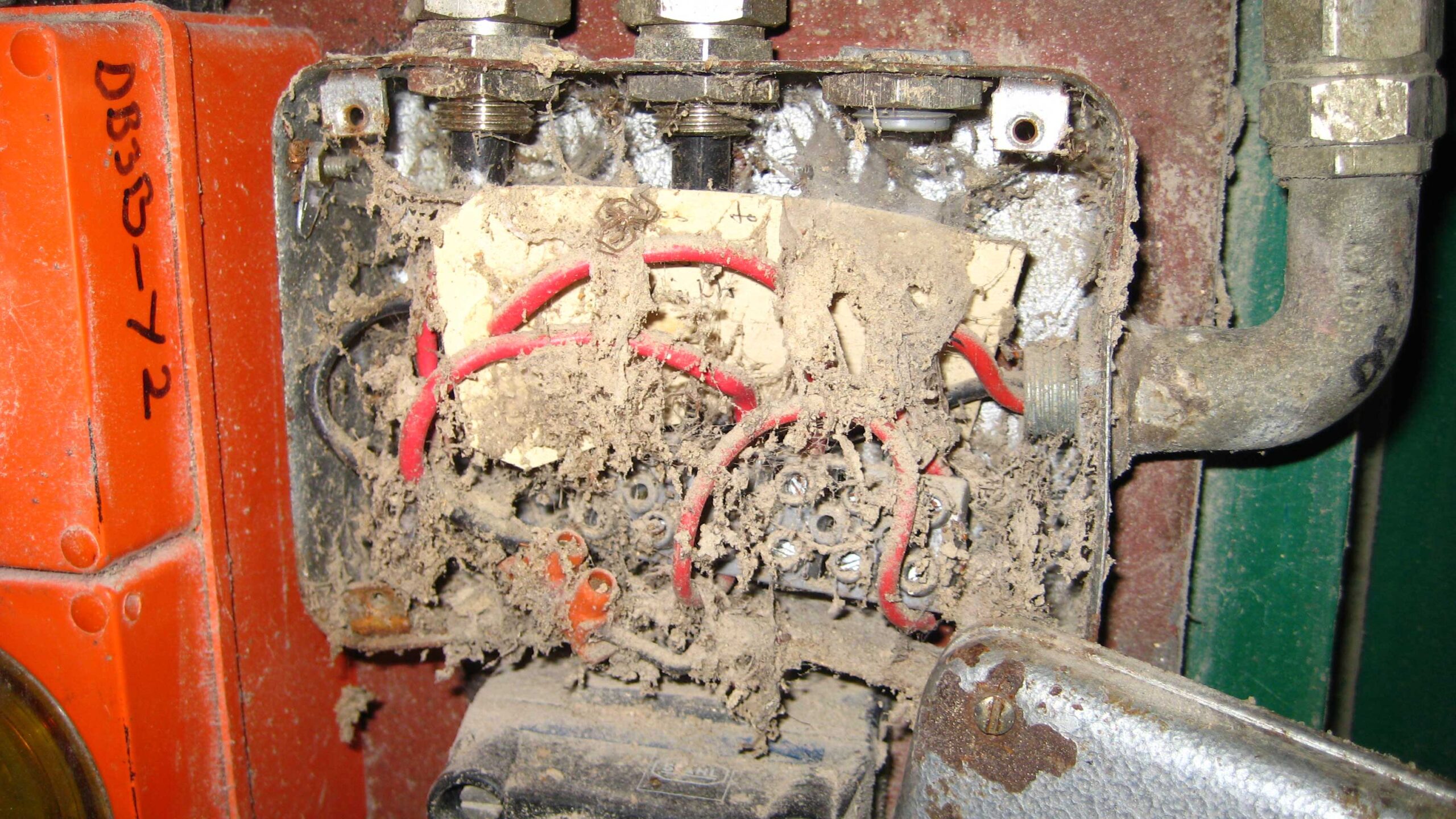

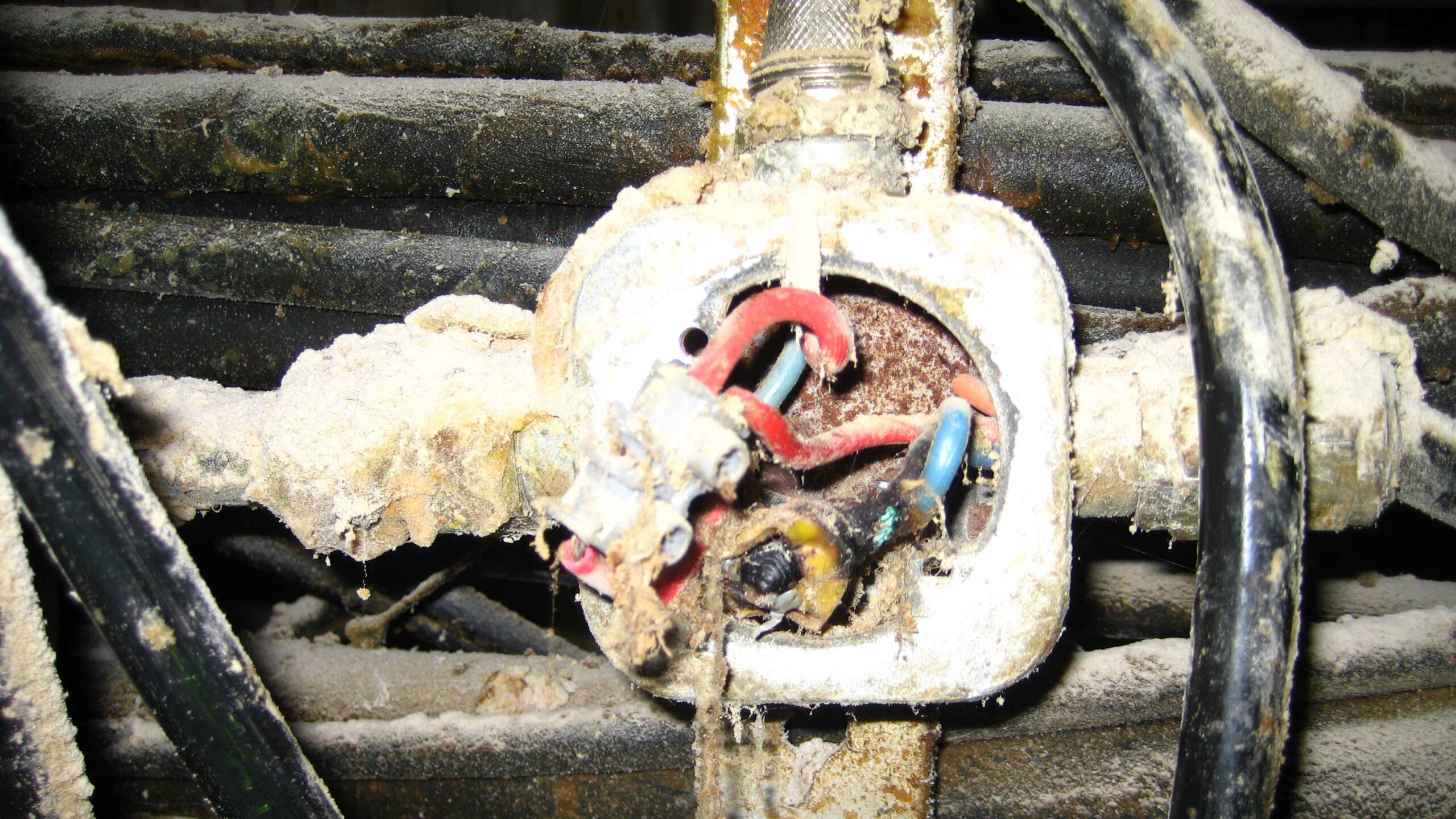

These particles are expelled into the air and can get into the electrical and mechanical parts of your equipment.

These particles include:

- Agricultural products: egg white, milk powder, sugar

- Agricultural dusts: grass dust, potato starch, tea

- Carbonaceous dusts: charcoal, corn, cellulose

- Chemical dusts: ascorbic acid, calcium acetate, lactose

- Metal dusts: aluminium, magnesium, zinc

- Plastic dusts: epoxy resin, melamine, polyethylene

The cost of inaction can far exceed the cost of safeguarding your business. Consider inviting a hazardous areas expert to assess your site and processes, and provide a comprehensive site report.

Benefits to your company

- Reduced risk of plant loss (fire and/or explosion)

- Potential cost savings on insurance premiums

- Improved plant reliability

- Compliance with Aotearoa New Zealand regulations, standards, and laws

- Confidence in operational safety

At ICE Electrical, our specialists in hazardous area electrical inspections offer a comprehensive service to assist with your site management.

We provide:

- A consultative approach to hazardous area assessments and advice

- Electrical project management and staffing at all levels

- Ongoing hazardous areas electrical inspections, from project initiation to completion, including verification and periodic managed inspections (every four years) as required by regulations, including registration on the electrical high-risk database.